OTHER OPTIONS

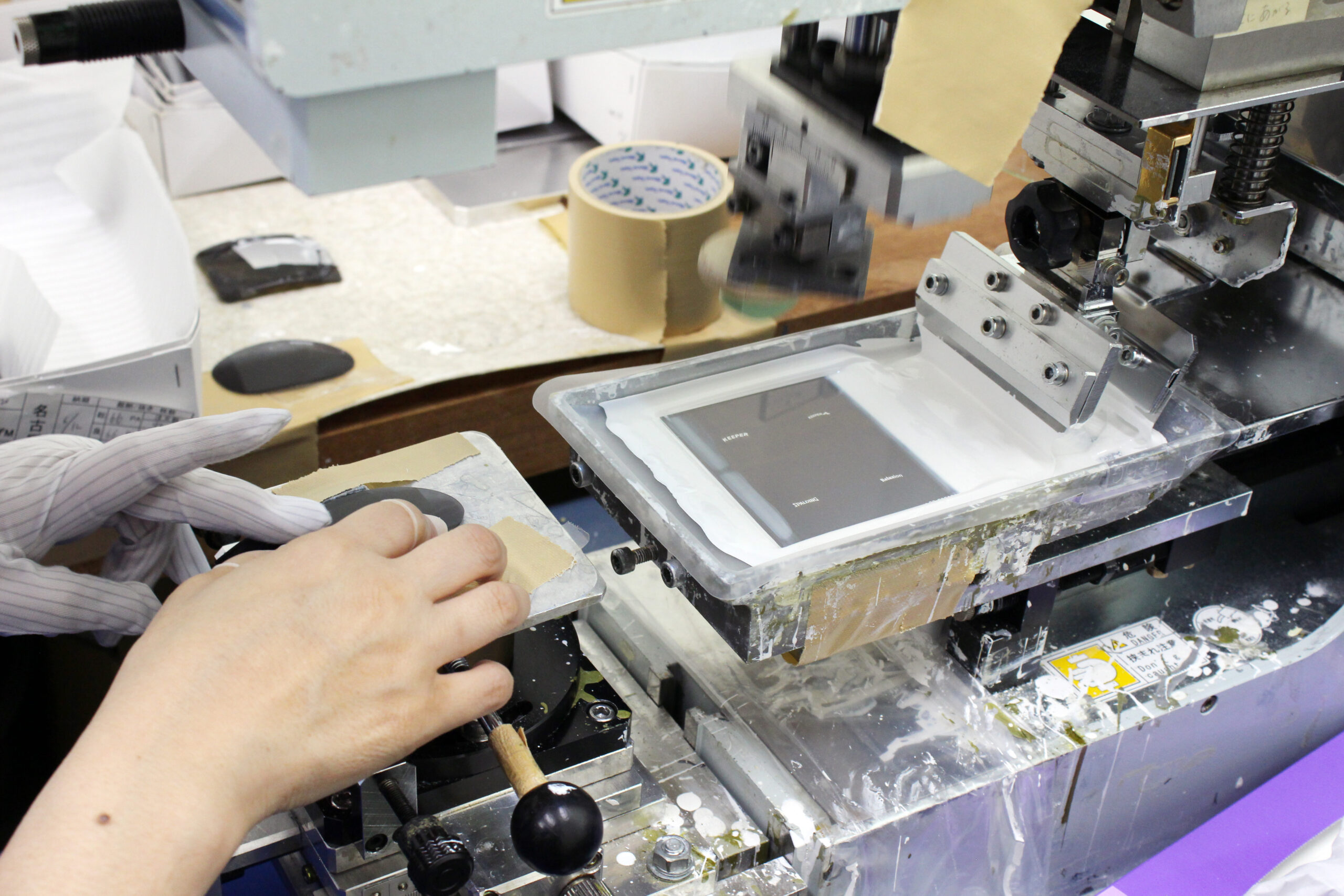

Printing Processing

We will print your desired logo and mark on frames and hardware as to your requests. Pad Printing – A great characteristic of pad printing is it is so versatile. A soft silicon rubber pad fits the curve of the material to be printed on . It is then layered or coated with the ink or printing material. Now it is possible to print not only on a flat surface but also on a curved surface or inside a concave surface as well. It also corresponds and is easily adapted to creating delicate designs.

Punching

We also use the Thomson type Punching machines to accommodate curved shapes.

Precision Frame Lens Insertions / Priority Packing

From our factory to your door, our lenses go through detailed inspections at every level. Our Lenses are processed and carefully packed according to the frames and boxes necessary. They are securely packed and framed, one by one, by hand. The lenses are thoroughly inspected and finished. Then they are securely boxed and ready to be shipped. Finally, the lenses are packed carefully again after applying stringent final checks for final shipping.

Inspection

There are no scratches, fogginess or distortions in the inspected lenses. Each piece, one by one, is light tested for illumination clarity. We then continue the inspection with human eyes. Careful Pairing is done after color matching so that there are no color anomalies, fading or color omissions.

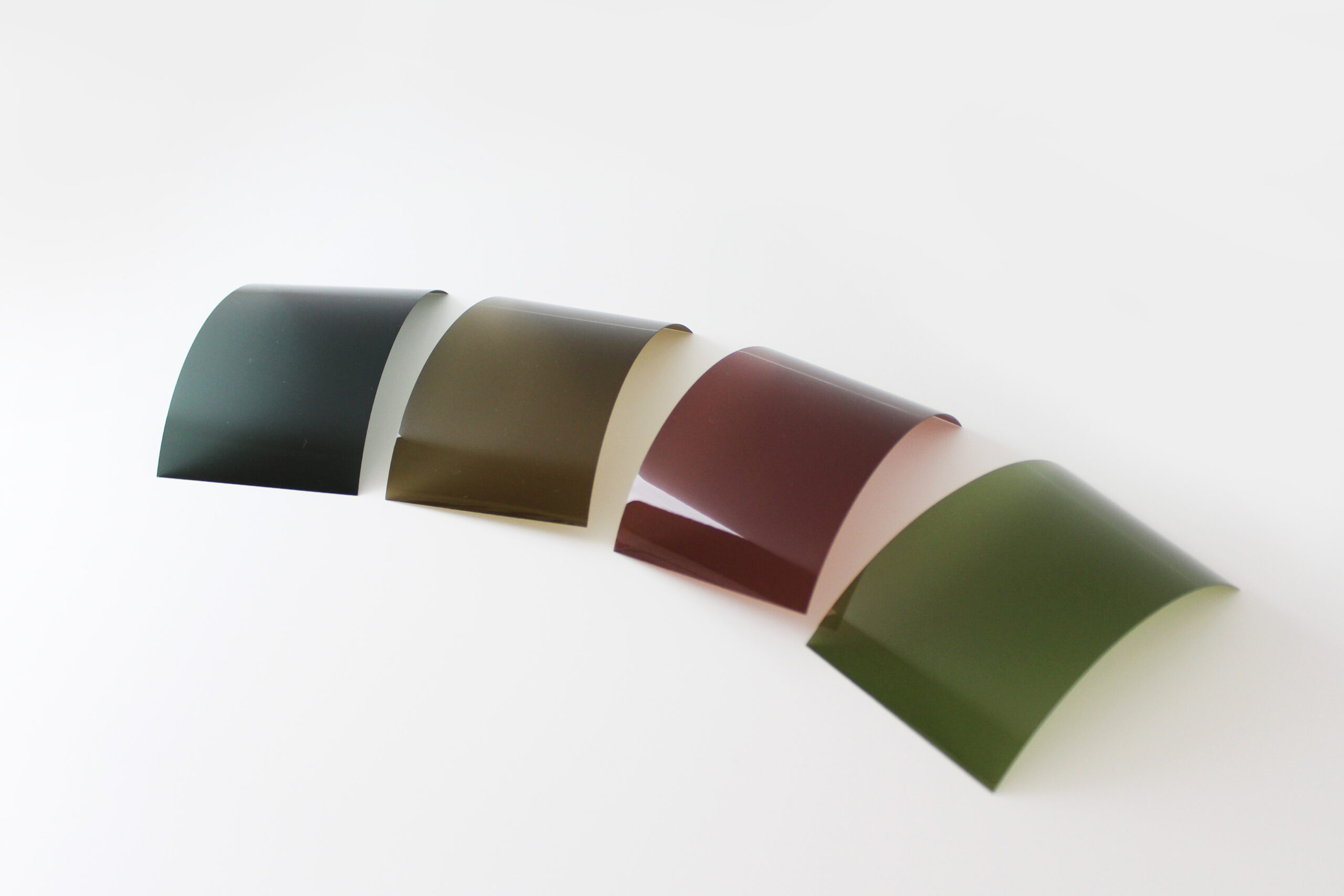

Superior Lens Coatings

Lens Coatings such as Mirror Coats and AR (Anti-Reflective) Coats are also popular. We gladly accept various coating requests.