CNC PROCESSING

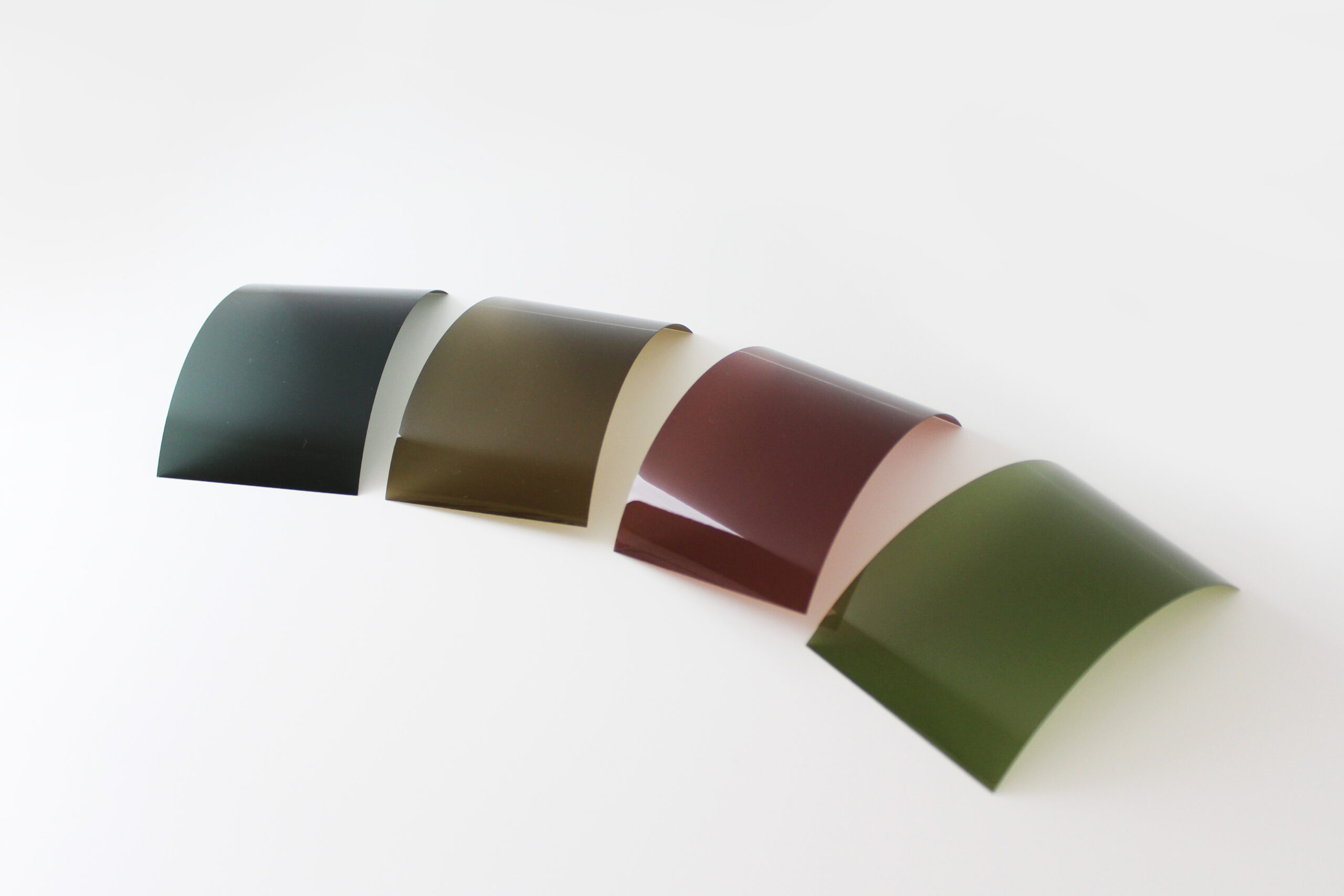

We will process each lens shape with our state of the art 5 axis control CNC processing machine. In addition to detail outline processing, batch processing such as precision drilling and cutting can be performed as well. We can easily deal with various processing orders such as single lens type or twin (double) lens type as can be found in ski goggles.

CNC processing

The State of CNC Processing

Our specialized CAD system converts the digital data of the lens shape designed with 2D or 3D CAD into a CAD dedicated processing machine and precision cuts the lenses to the designed shape and dimensions.

Our state of the art CNC processing machine is now completely automated. We always strive to offer the perfect balance of impeccable quality, reasonable cost and incredibly swift delivery time along with our dedication to excellence.

Our specialized and sophisticated system converts to CAD data that is exclusive for our processing machine utilizing the CAD data and details created by our customers.

※ If, for whatever reason, the CAD data can not be prepared by our customers, we will be happy to custom create the CAD data for you based on the precise lens shape sample and sunglasses frame you provide.

NORMAL / STANDARD TYPE PROCESSING

We will carefully precision process the lenses for sunglasses as well as the lenses for presbyopic glasses into a pleasing yet simple and attractive eye shape.

We are using this extensively for designing and making samples and processing precision presbyopic lenses.

※The Processing Data is created based on the exact lens shape sample and sunglasses frame.

( As you may already know, Presbyopia is when your eyes gradually lose the ability to see things clearly up close. Therefore presbyopic lenses are an ideal choice for certain individuals. )